Chipboard is one of those materials that gets a bad name for being weaker than solid timber, but what most people miss is just how revolutionary the idea is. When used for the right applications, it’s just perfect and lasts well, and what’s more, the manufacture of chipboard uses up scraps and cuttings that would otherwise be thrown out. It reduces waste and in these environmentally conscious times surely we should give it a round of applause for that reason alone.

It’s true that a cut to size chipboard section may not be as strong as a single solid plank of hardwood but then, it often doesn’t have to be. The shelving in most kitchen cupboards doesn’t need to support a huge weight and in many cases Melamine Faced Chipboard (MFC) does the job perfectly well.

The melamine is a plastic coating that seals out moisture. This is quite important as the inner material can weaken when it gets damp, but there are other advantages. The smooth, waterproof melamine surface wipes clean, unlike raw timber, and it’s quite resistant to stains. MFC is cheap and easy to produce in a rainbow of different colours.

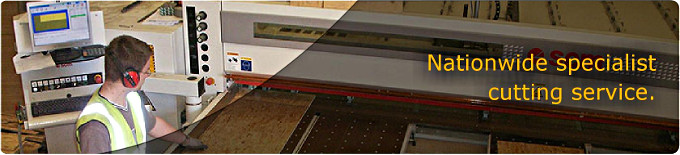

It isn’t suitable for every project but no single material is ideal for everything. In the right place it is an eco friendly, low cost option that performs well. We can provide chipboard or MFC precision shaped with computerised CNC cutting tools. If you’ve got a task and think chipboard is the way forward, we can create just what you want.